Fàilte gu na làraichean-lìn againn!

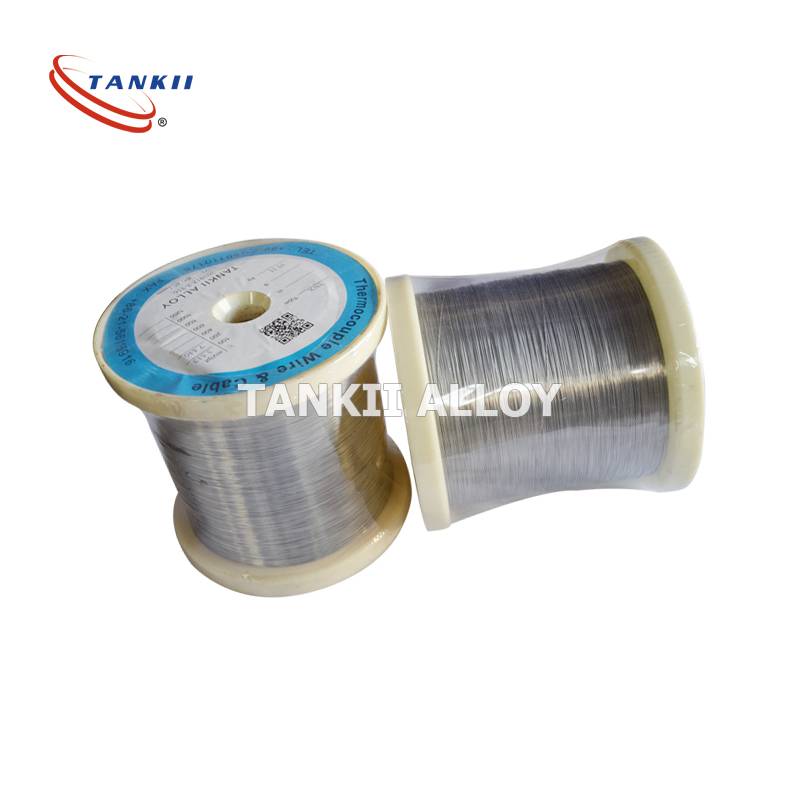

Uèir dealain teas-dhìonach FeCrAl FeCr23Al5 A1 APM AF D Alloy

Uèir dealain a tha an aghaidh teas FeCrAl A1 APM AF D Alloy

Mu dheidhinn Uèir Teasachaidh Resistance:

Is sinne an neach-dèanamh proifeasanta as motha de aloidhean teasachaidh strì an aghaidh ann an Sìona, a’ speisealachadh ann an uèir Ferro-Chrome (Fe-Cr-AL), uèir Nickel-Chrome (Nichrome), uèir Copar Nickel (Constantan), uèir stàilinn gun staoin agus toraidhean co-cheangailte ann an aloidhean a tha air an dealbhadh gus coinneachadh ri riatanasan sònraichte luchd-ceannach.

Mion-fhiosrachadh meud

| Ainm an toraidh | Raon meud |

| Uèir tarraing fuar | Trast-thomhas 0.03-7.5mm |

| Slat uèir teth-roilichte | Trast-thomhas 8.0-12mm |

| Ribbon | Tiughas 0.05-0.35mm |

| Leud 0.5.0-3.5mm | |

| Stiall fuar-roilichte | Tiughas 0.5-2.5mm |

| Leud 5.0-40mm | |

| stiall teth-roilichte | Tiughas 4-6mm |

| Leud 15-40mm |

paramadairean bunaiteach:

| paramadairean bunaiteach | APMTM | FeCrAl | ||

| A-1 | AF | D | ||

| An teòthachd obrach leantainneach as àirde | 1425 | 1400 | 1300 | 1300 |

| An co-dhèanamh ceimigeach ainmichte,% Cr | 22 | 22 | 22 | 22 |

| AI | 5.8 | 5.8 | 5.3 | 4.8 |

| Fe | grìtheidean | grìtheidean | grìtheidean | grìtheidean |

| Ni | - | - | - | - |

| An aghaidh-sheasmhachd ann an 20ºC, Ωmm-2mm-1 | 1.45 | 1.45 | 1.39 | 1.35 |

| dùmhlachd, g/cm3 | 7.1 | 7.1 | 7.15 | 7.25 |

| Co-èifeachd leudachaidh teirmeach K-1 20-750ºC | 14 × 10-6 | 14 × 10-6 | 14 × 10-6 | 14 × 10-6 |

| 20-1000ºC | 15 × 10-6 | 15 × 10-6 | 15 × 10-6 | 15 × 10-6 |

| An giùlan teirmeach 20ºC, Wm-1K-1 | 13 | 13 | 13 | 13 |

| Comas teas sònraichte 20ºC, KJkg-1K-1 | 0.46 | 0.46 | 0.46 | 0.46 |

| Puing leaghaidhºC | 1500 | 1500 | 1500 | 1500 |

| Is dòcha feartan meacanaigeach | ||||

| Neart teannachaidh, N mm-2 | 680 | 680 | 680 | 650 |

| Neart an toraidh, N mm-2 | 470 | 475 | 475 | 450 |

| Cruas, Hv | 230 | 230 | 230 | 230 |

| Leudachadh briseadh,% | 20 | 18 | 18 | 18 |

| 900ºC Neart teannachaidh, N mm-2 | 40 | 34 | 37 | 34 |

| Neart snàgadh 800ºC | 11 | 6 | 8 | 6 |

| 1000ºC | 3.4 | 1 | 1.5 | 1 |

| Magnetic | magnetach (Anns an teòthachd 600ºC) | |||

| Sgaoileadh, na cumhaichean ocsaididh | 0.7 | 0.7 | 0.7 | 0.7 |

Sònrachadh:

| Seòrsa aloidh | Trast-thomhas | Frith-sheasmhachd | Teanntachd | Leudachadh (%) | Lùbadh | Uasmhéid leantainneach | Beatha-obrach |

| (mm) | (μΩm)(20°C) | Neart | Amannan | Seirbheis | (uairean) | ||

| (N/mm²) | Teòthachd (°C) | ||||||

| Cr20Ni80 | <0.50 | 1.09±0.05 | 850-950 | >20 | >9 | 1200 | >20000 |

| 0.50-3.0 | 1.13±0.05 | 850-950 | >20 | >9 | 1200 | >20000 | |

| >3.0 | 1.14±0.05 | 850-950 | >20 | >9 | 1200 | >20000 | |

| Cr30Ni70 | <0.50 | 1.18±0.05 | 850-950 | >20 | >9 | 1250 | >20000 |

| ≥0.50 | 1.20±0.05 | 850-950 | >20 | >9 | 1250 | >20000 | |

| Cr15Ni60 | <0.50 | 1.12±0.05 | 850-950 | >20 | >9 | 1125 | >20000 |

| ≥0.50 | 1.15±0.05 | 850-950 | >20 | >9 | 1125 | >20000 | |

| Cr20Ni35 | <0.50 | 1.04±0.05 | 850-950 | >20 | >9 | 1100 | >18000 |

| ≥0.50 | 1.06±0.05 | 850-950 | >20 | >9 | 1100 | >18000 | |

| 1Cr13Al4 | 0.03-12.0 | 1.25±0.08 | 588-735 | >16 | >6 | 950 | >10000 |

| 0Cr15Al5 | 1.25±0.08 | 588-735 | >16 | >6 | 1000 | >10000 | |

| 0Cr25Al5 | 1.42±0.07 | 634-784 | >12 | >5 | 1300 | >8000 | |

| 0Cr23Al5 | 1.35±0.06 | 634-784 | >12 | >5 | 1250 | >8000 | |

| 0Cr21Al6 | 1.42±0.07 | 634-784 | >12 | >5 | 1300 | >8000 | |

| 1Cr20Al3 | 1.23±0.06 | 634-784 | >12 | >5 | 1100 | >8000 | |

| 0Cr21Al6Nb | 1.45±0.07 | 634-784 | >12 | >5 | 1350 | >8000 | |

| 0Cr27Al7Mo2 | 0.03-12.0 | 1.53±0.07 | 686-784 | >12 | >5 | 1400 | >8000 |

Buannachd:

Tha strì an aghaidh creimeadh, oxidation uachdar agus neart teothachd àrd, ductility math, agus comas obrachaidh agus tàthaidh math aig aloi nicil-chromium.

Sgrìobh do theachdaireachd an seo agus cuir thugainn i

Roinnean thoraidhean

-

Fòn

-

Post-d

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Barr